What are the Product Standards for Hot-Selling Angle Steel?

I. Introduction

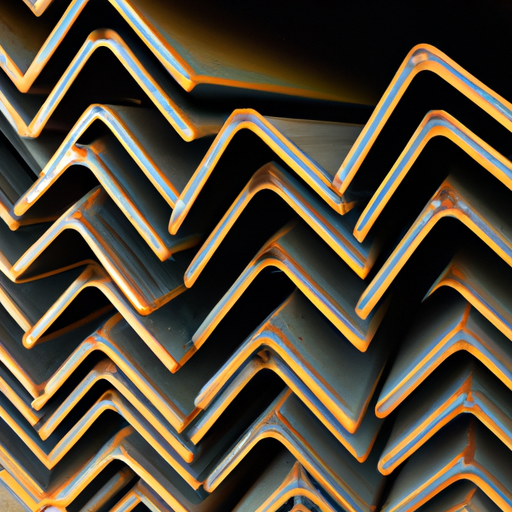

Angle steel, also known as angle iron, is a versatile structural steel product that is widely used in various industries. Defined as a steel bar with an L-shaped cross-section, angle steel is available in different sizes and thicknesses, making it suitable for a range of applications. The importance of product standards in the manufacturing and use of angle steel cannot be overstated. These standards ensure that the products meet specific quality, safety, and performance criteria, which are essential for their effective use in construction, manufacturing, and infrastructure projects. This article will explore the product standards for hot-selling angle steel, highlighting their significance, key specifications, and compliance considerations.

II. Understanding Angle Steel

A. Definition and Characteristics

Angle steel is characterized by its L-shaped cross-section, which provides excellent strength and stability. The dimensions of angle steel are typically defined by the length of the legs and the thickness of the material. Common sizes range from 20 mm to 200 mm in leg length, with thicknesses varying from 3 mm to 20 mm. The material composition of angle steel usually consists of carbon steel, although alloying elements may be added to enhance specific properties.

B. Common Applications

Angle steel is widely used in various applications, including:

1. **Construction**: Angle steel is commonly used in the construction of buildings, bridges, and other structures. It serves as a key component in frameworks, supports, and bracing systems.

2. **Manufacturing**: In manufacturing, angle steel is utilized in the production of machinery, equipment, and storage systems. Its strength and durability make it ideal for heavy-duty applications.

3. **Infrastructure**: Angle steel is also employed in infrastructure projects, such as railways and highways, where it provides structural support and stability.

III. Importance of Product Standards

A. Ensuring Quality and Safety

Product standards play a crucial role in ensuring the quality and safety of angle steel. By adhering to established standards, manufacturers can produce steel that meets specific performance criteria, reducing the risk of structural failures and accidents.

B. Facilitating Trade and Market Access

Compliance with international and national standards facilitates trade by ensuring that products can be sold in various markets. This is particularly important for manufacturers looking to expand their reach and compete globally.

C. Enhancing Performance and Durability

Standards help enhance the performance and durability of angle steel by specifying material properties, dimensions, and testing methods. This ensures that the steel can withstand the demands of its intended applications.

IV. Key Product Standards for Angle Steel

A. International Standards

1. **ISO Standards**: The International Organization for Standardization (ISO) has developed several standards related to steel products, including angle steel. These standards cover aspects such as material properties, testing methods, and quality assurance.

2. **ASTM Standards**: The American Society for Testing and Materials (ASTM) provides standards that are widely recognized in the steel industry. ASTM standards for angle steel include specifications for chemical composition, mechanical properties, and testing procedures.

B. National Standards

1. **American Standards**: In the United States, common standards for angle steel include ASTM A36, which specifies carbon structural steel shapes, and ASTM A992, which is used for wide-flange structural shapes.

2. **European Standards**: In Europe, standards such as EN 10056 and EN 10025 outline the requirements for structural steel products, including angle steel, focusing on material properties and testing methods.

3. **Chinese Standards**: In China, GB/T 9787 and GB/T 700 are key standards that govern the production and quality of angle steel, ensuring compliance with national requirements.

C. Industry-Specific Standards

Different industries may have specific standards that apply to angle steel. For example, the construction industry may have additional requirements related to load-bearing capacity and seismic performance, while the manufacturing industry may focus on precision and tolerances.

V. Material Specifications

A. Chemical Composition

The chemical composition of angle steel is critical to its performance. Key elements include:

1. **Carbon Content**: The carbon content typically ranges from 0.2% to 0.3%, which affects the steel's strength and hardness.

2. **Alloying Elements**: Elements such as manganese, silicon, and chromium may be added to enhance specific properties, such as corrosion resistance and toughness.

B. Mechanical Properties

Mechanical properties are essential for determining the performance of angle steel. Key properties include:

1. **Yield Strength**: This is the stress at which the material begins to deform plastically. Higher yield strength indicates better load-bearing capacity.

2. **Tensile Strength**: This measures the maximum stress that the material can withstand while being stretched or pulled before breaking.

3. **Elongation**: This property indicates the material's ability to deform under tensile stress, which is crucial for applications requiring flexibility.

VI. Dimensional Standards

A. Standard Sizes and Tolerances

Angle steel is available in standard sizes, with specific tolerances defined by various standards. These tolerances ensure that the steel can be accurately fitted and assembled in construction and manufacturing applications.

B. Weight Specifications

Weight specifications are also important, as they affect transportation and handling. Standards provide guidelines for the weight of angle steel based on its dimensions and material composition.

C. Surface Finish Requirements

Surface finish requirements are essential for preventing corrosion and ensuring the longevity of angle steel. Standards may specify treatments such as galvanization or painting to enhance corrosion resistance.

VII. Testing and Certification

A. Types of Tests

To ensure compliance with product standards, angle steel undergoes various tests, including:

1. **Mechanical Testing**: This includes tensile tests, yield strength tests, and impact tests to assess the material's mechanical properties.

2. **Chemical Analysis**: Chemical tests are conducted to verify the composition of the steel and ensure it meets specified standards.

3. **Non-Destructive Testing**: Techniques such as ultrasonic testing and magnetic particle testing are used to detect internal defects without damaging the material.

B. Certification Bodies

Certification bodies play a vital role in ensuring compliance with standards. Key organizations include:

1. **ISO Certification**: Manufacturers may seek ISO certification to demonstrate adherence to international quality standards.

2. **National Standards Organizations**: Organizations such as ASTM and ANSI provide certification for compliance with national standards.

VIII. Compliance and Regulatory Considerations

A. Importance of Compliance

Compliance with product standards is essential for manufacturers and users of angle steel. It ensures that the products are safe, reliable, and suitable for their intended applications.

B. Consequences of Non-Compliance

Failure to comply with standards can result in serious consequences, including structural failures, legal liabilities, and damage to reputation. It can also lead to increased costs due to rework or replacement of non-compliant products.

C. Role of Regulatory Bodies

Regulatory bodies oversee compliance with standards and regulations, conducting inspections and audits to ensure that manufacturers adhere to established guidelines.

IX. Trends and Innovations in Angle Steel Standards

A. Advances in Material Science

Recent advances in material science have led to the development of new steel alloys and treatments that enhance the performance of angle steel. These innovations may lead to updated standards that reflect the latest technological advancements.

B. Sustainability and Environmental Standards

As sustainability becomes a priority in the construction and manufacturing industries, new standards are emerging that focus on the environmental impact of steel production and use. This includes guidelines for recycling and reducing carbon emissions.

C. Future Directions in Product Standards

The future of product standards for angle steel will likely involve greater emphasis on performance, sustainability, and innovation. As industries evolve, standards will need to adapt to meet new challenges and requirements.

X. Conclusion

In conclusion, product standards for hot-selling angle steel are essential for ensuring quality, safety, and performance in various applications. By adhering to international, national, and industry-specific standards, manufacturers can produce reliable and durable products that meet the needs of their customers. Compliance with these standards not only facilitates trade and market access but also enhances the overall performance of angle steel. As the industry continues to evolve, staying informed about trends and innovations in product standards will be crucial for manufacturers and users alike.

XI. References

- ISO Standards for Steel Products

- ASTM Standards for Structural Steel

- EN Standards for European Steel Products

- GB Standards for Chinese Steel Products

- Relevant literature on material science and sustainability in steel production

This comprehensive overview of product standards for angle steel provides valuable insights for manufacturers, engineers, and industry professionals, emphasizing the importance of quality and compliance in the steel industry.